In modern fruit and vegetable processing, the washing stage is the critical first step in ensuring product quality, safety, and customer satisfaction. For fruits like blueberries—which feature a small, deeply wrinkled surface and are prone to damage—relying solely on manual washing is not only time-consuming and labor-intensive but also struggles to remove dirt, pesticide residues, and impurities thoroughly. Therefore, selecting a professional blueberry cleaner is essential for improving blueberry cleaning efficiency. This article shares technical solutions and equipment advantages for washing blueberries, helping you precisely address blueberry cleaning challenges.

Why is a Professional Bubble Washer Needed for Blueberries?

Blueberries feature complex, fragile surfaces with fine crevices that traditional water washing struggles to clean thoroughly. Using a professional fruit and vegetable washer enables:

- Efficient removal of dirt, dust, and pesticide residues

- Prevention of fruit damage caused by manual scrubbing

- Enhanced production efficiency and reduced labor costs

- Seamless integration with subsequent processing (sorting, packaging, etc.)

These represent the core needs most frequently sought by customers searching for how to wash blueberries.

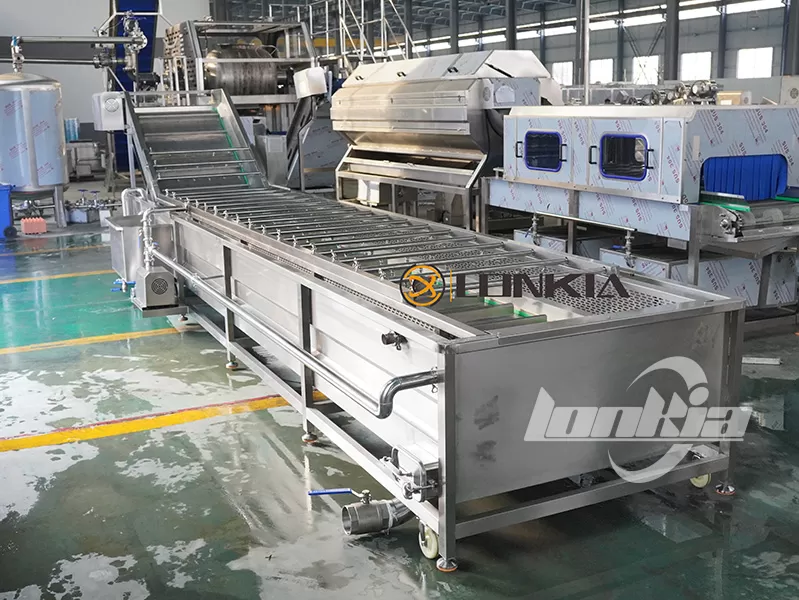

Blueberry Cleaner Workflow

How to wash blueberries? The correct steps are as follows:

- Pre-treatment feeding: Evenly pour blueberries into the feed inlet.

- Bubble washing stage: Bubble water flow agitates the fruit, separating dirt and sand.

- Secondary hydraulic rinsing: Utilizes spray nozzles and rollers to remove residual contaminants further.

- Vibration dewatering: Reduces surface moisture through vibrating dehydration.

- Discharge Collection: Clean blueberries are collected via the discharge outlet for subsequent processing or packaging.

This blueberry processing line design saves labor while ensuring consistent and stable overall cleaning results.

What to Consider When Selecting a Blueberry Cleaner?

For customers preparing to invest in equipment, selecting suitable washing machinery requires focusing on the following aspects:

✦ Cleaning Effectiveness

Can it thoroughly remove sand, silt, and pesticide residues? Are the washed blueberries intact and undamaged? These are direct indicators of equipment quality.

✦ Capacity Matching

Select a blueberry washing machine with appropriate capacity (e.g., 500kg/h, 1000kg/h) based on daily production volume to avoid undercapacity or wasted investment.

✦ Ease of Operation

Design features like ease of cleaning/maintenance, intuitive control panels, and durable components significantly impact daily production efficiency.

✦ Service Support

Comprehensive after-sales support and timely technical guidance ensure long-term, stable equipment operation.

Summary

For delicate small fruits like blueberries, professional blueberry cleaners offer greater efficiency, hygiene, and cost savings compared to manual cleaning. Modern washing equipment delivers standardized, high-quality cleaning solutions through bubble washing, secondary spraying, and segmented conveyor line design. This not only significantly enhances product quality but also boosts production efficiency.

For in-depth consultation on blueberry washing equipment solutions tailored to your production needs, contact professional cleaning machinery manufacturers like LONKIA. They can provide customized recommendations based on your output volume, facility space, and fruit characteristics.