When selecting a garlic peeling machine, production capacity is one of the key parameters customers prioritize. It directly impacts production efficiency and return on investment. Different processing plants have varying output requirements. Insufficient capacity can create production bottlenecks, while excessively high capacity may lead to energy waste. Therefore, understanding the machine's hourly garlic processing volume is crucial for making informed purchasing decisions.

Primary Factors Affecting Garlic Peeling Machine Capacity

1. Pneumatic System Efficiency

Most garlic peeling machines operate on pneumatic principles, where stable air pressure directly impacts peeling speed and yield. Insufficient pressure reduces output, while excessive pressure may damage cloves.

2. Garlic Dryness/Moisture Content

The moisture level of raw garlic affects peeling effectiveness. Moderately dry cloves peel more cleanly, increasing hourly throughput.

3. Drum and Peeling Chamber Design

High-quality stainless steel drum construction and optimized feed channels enable continuous operation, minimize jamming, and accelerate overall processing speed.

4. Automatic Feeding System

Machines equipped with automatic feeders achieve uninterrupted operation, reduce manual intervention, and enhance overall production efficiency.

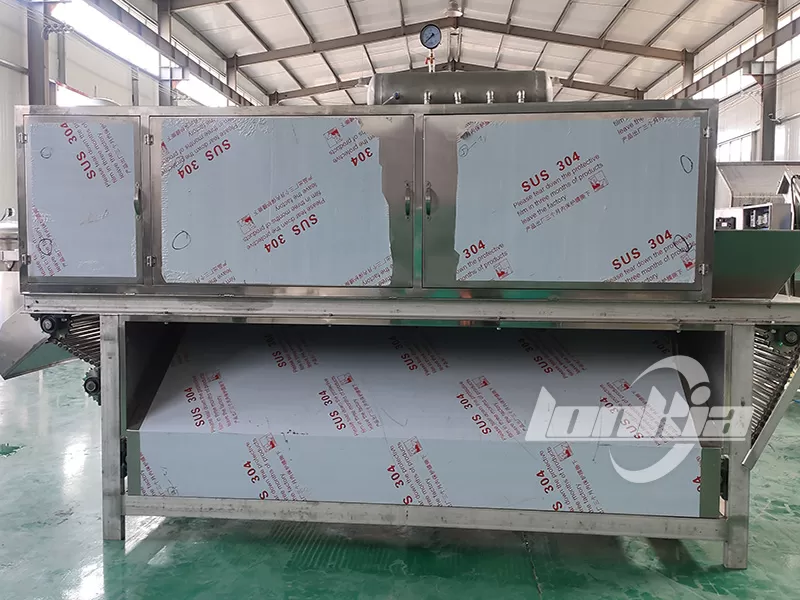

Lonkia Industrial Garlic Peeler Capacity Range

Lonkia's industrial garlic peelers, depending on model configuration, can process 100 to 600 kilograms of garlic per hour. Constructed from food-grade stainless steel and featuring an efficient pneumatic peeling system, the equipment ensures high clove integrity and consistent peel removal rates.

Under continuous production conditions, the machine seamlessly integrates feeding and discharging processes, significantly boosting overall processing line efficiency. It is suitable for medium to large-scale food processing plants.

Selecting Appropriate Capacity Based on Requirements

- Medium-Volume Clients: Opt for garlic peeling machine around 300kg/h to balance output and energy consumption.

- Large-Scale Processing Plants: Choose models of 500kg/h or higher, compatible with automated feeding systems and assembly line production.

Before selection, clients should calculate total daily processing volume and production shifts to determine capacity needs. Manufacturers can then provide tailored solutions ensuring equipment output aligns with factory production targets.

Conclusion

Selecting a garlic peeling machine with appropriate capacity not only enhances production efficiency but also effectively reduces labor costs and raw material waste. Lonkia specializes in the R&D and manufacturing of food processing equipment, providing stable and efficient electric garlic peeler solutions to help customers build high-efficiency, reliable garlic processing production systems.