In today’s fast-paced food industry, cleanliness, efficiency, and productivity are non-negotiable. For businesses involved in processing vegetables, ensuring the removal of soil, pesticides, and contaminants is critical. That’s where a vegetable bubble washing machine becomes a game-changer.

This article explores the key benefits of using a bubble washer and how it can improve hygiene standards, save time, and boost your production line efficiency.

1. Superior Cleaning Through Air Bubble Technology

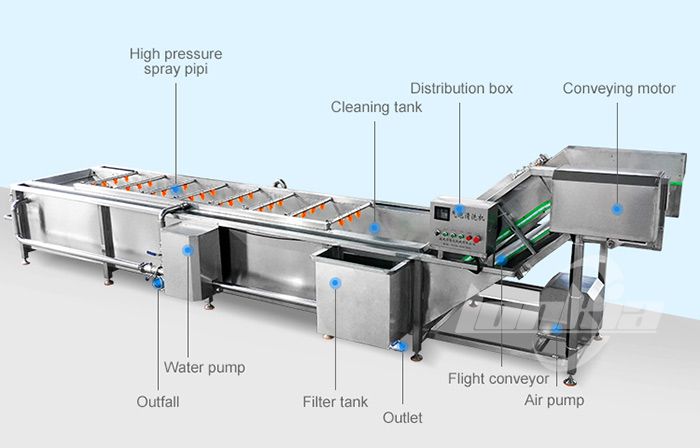

The bubble washing machine works by generating millions of tiny air bubbles that agitate water and dislodge dirt, sand, and residues from the surface of vegetables. This mimics manual scrubbing — but with greater consistency and zero physical contact.

Key advantages:

Effectively removes stubborn particles from leafy greens, root vegetables, and fruits

Gentle on delicate produce like spinach or strawberries

No damage or bruising to product surface

2. Ensures Food Safety and Hygiene

Meeting food safety standards is essential in every processing facility. A bubble washing machine reduces human handling and uses continuous clean water circulation to wash away contaminants, helping you:

Minimize the risk of cross-contamination

Improve microbial control

Comply with HACCP and GMP standards

Many machines also support ozone or chlorine integration, further enhancing disinfection.

3. Boosts Productivity and Labor Efficiency

Traditional manual washing is labor-intensive, inconsistent, and time-consuming. In contrast, a vegetable bubble washing machine:

Handles hundreds of kilograms of vegetables per hour

Requires minimal supervision

Integrates easily with conveyor belts or drying systems

Reduces overall labor costs and reliance on skilled workers

Whether for central kitchens, frozen vegetable producers, or pickled food factories, the machine streamlines the washing process.

4. Versatility Across Different Vegetable Types

Bubble washers are not limited to leafy vegetables. Their flexible design accommodates:

Leafy greens: lettuce, spinach, cabbage

Root vegetables: carrots, potatoes, radishes

Soft fruits: tomatoes, strawberries

Herbs and mushroom varieties

With adjustable water flow and air volume, one machine can handle multiple product types without compromising results.

5. Eco-Friendly and Water-Efficient Operation

Many modern vegetable bubble washers feature closed-loop water circulation systems, allowing for water reuse and reduced wastewater output. Paired with optional filtration systems, these machines are:

Environmentally sustainable

Cost-saving in water consumption

Easy to integrate with waste treatment lines

6. Easy Maintenance and Durable Structure

Most machines are built with food-grade SUS304 stainless steel, ensuring:

Corrosion resistance

Long lifespan under continuous use

Simple cleaning and maintenance routines

Components like bubble generators, conveyors, and water tanks are modular and easy to service, reducing downtime.

Conclusion

A vegetable bubble washing machine is a must-have investment for food processors who prioritize hygiene, speed, and efficiency. Whether you're a small-scale farm-to-table operation or a large-volume vegetable processor, adopting this technology helps you elevate product quality, reduce labor costs, and meet rigorous food safety standards.

✅ Ready to upgrade your washing system? Contact us for expert recommendations based on your product type and production volume.